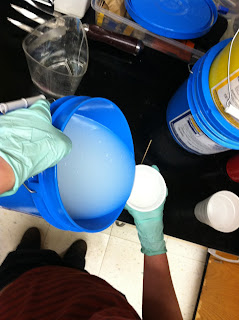

Hi, we've been waiting on materials for our prototype and some finally came in (and the deadline approached) so we made our first prototype. On Monday (4/9) we made molds for the shell of the vac-cast using the thermo former. We ended up trying to combine two different thermoformed pieces to create the correct shape for the silicon. We used the 2 types of silicon in the lab to create shells for our prototype. The molds we created were not flat, so the silicon shells were not as uniformly distributed as we had hoped for. In the silicon we saw in the Media Lab the forms were all made from smaller, flat pieces and then bend into the appropriate shapes.

Thermoformer

Ring made of sculpter's molding clay

You can see the thermoformed plastic shell above

The 2 thermoformed pieces taped together

view from the top

mixing the silicon

Silicon in aluminum tray

The thermoformed mold filled with silicon

We also thought about casing and decided that a case that was also where the case would be made would be optimal. We used a 5 gallon bucket for the case and attached a bicycle value to it, which would allow vacuum to pull the air out and then it could seal the container.

-Megan

No comments:

Post a Comment