This is the home screen.

As the app opens this image appears. It asks "What's wrong?" and the user gets to choose the part that failed by clicking the buttons at the bottom.

If the shell button is pressed, this screen will appear which lists possible good and bad materials that the consumer might use to replace the shell. It ranked them in term of cost and how well they work. If a choice is selected, the app will give more details about what that material looks like and where you could find it.

If the filling button is pressed the user will be directed towards this screen which does the same as the shell screen above.

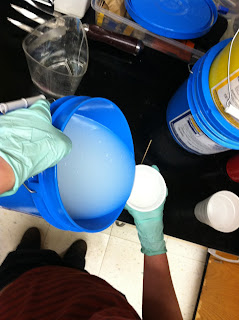

And if the Bucket button is pressed the user will be directed towards this screen, which works as the 2 screen above it do.

-Megan